We have all seen that you have put a significant amount of time into this truck.

I personaly think it would be cool if and when you get to a point that you think you got it as good as you can get, and it is fairly plug and play.

It would be cool to see a build sheet that others could use.

I mean it may never get to that point, but you never know.

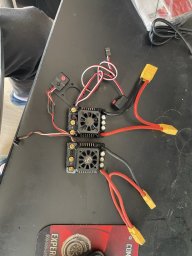

other than the rear motor mount/wing mount/wheelie bar mount, someone could pull off our build (or close to it) with more or less off the shelf aftermarket parts, and the rear mount can be done with just the ax10 trans as many others have. we are in a position where both the new chassis is not ready to run yet and where we'd like to see where the ceiling of this one is - I think it's north of 60. I'll keep a build sheet in mind. Ruckus will eventually be retired to a much more mild setup for yard bashing, probably 4s/max10/3674 again.

There is a guy on the speed group who claims to have done 58mph with a 2wd Slash but the video and GPS don't really meet requirements - I have no doubt he actually did it, we have been helping him out for months with setup. Running a number bigger than that would