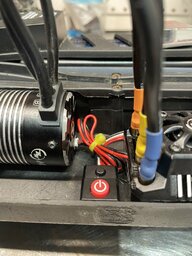

The big bazooka is here - 3660 4000kV Hobbywing to pair with the Max 10 SCT ESC. Wanted the low end grunt it offers over the 3652. Highest kV they offer capable of 3S. Finally will be able to use that temperature input for the ESC. We will be watching temps closely (I still am on 11/45, stock is 9/45). Will we need a 4WD wheelie bar?

Awaiting gap in weather...God damn mod1 gearing is LOUD.

Awaiting gap in weather...God damn mod1 gearing is LOUD.

Attachments

-

DEA16548-E6FB-4CD7-8094-6F3CFF8D4E36.jpeg229 KB · Views: 1

DEA16548-E6FB-4CD7-8094-6F3CFF8D4E36.jpeg229 KB · Views: 1 -

75A329F2-34F0-4D67-8C57-8241BA6F4DDF.jpeg174.6 KB · Views: 2

75A329F2-34F0-4D67-8C57-8241BA6F4DDF.jpeg174.6 KB · Views: 2 -

CE45C7DF-0C83-426C-BC4F-D1EB09BCE6E3.jpeg268 KB · Views: 2

CE45C7DF-0C83-426C-BC4F-D1EB09BCE6E3.jpeg268 KB · Views: 2 -

68E1F373-743B-44A3-A991-2FAEC27DB2C5.jpeg242.5 KB · Views: 1

68E1F373-743B-44A3-A991-2FAEC27DB2C5.jpeg242.5 KB · Views: 1 -

44852731-6B19-43AB-B7A3-E41C38A3365E.jpeg146.7 KB · Views: 1

44852731-6B19-43AB-B7A3-E41C38A3365E.jpeg146.7 KB · Views: 1

Last edited: