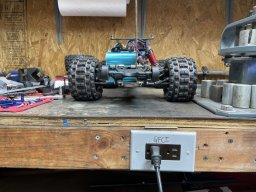

And where we are at right now...finally ordered the matching 4S battery so I can get rid of this 2x2s plus adapters situation, mod1 spur is on the way, and all of a sudden I had zero forward propulsion. Pulled it apart, and sure enough, the pin that holds the final drive gear on sheared clean off. I got lucky that it wasn't something more difficult/expensive and I was able to fish the pieces out relatively easily. I found the "upgrade" most guys are doing is taking high speed steel drill blanks and cutting them to length so I ordered some up. If I can't make this work I guess I have to go back to the other trans...which means making a new motor plate...ugh. There isn't a one piece output shaft option (in this gear ratio) like I have in the other one.