Rebuilt the front shocks (using the 4WD ones) by taking 10mm of travel out so it doesn't any longer bind the steering on full extension. Found metal lower shock ends that will work, and using a 2WD aluminum perch with a 4WD upper perch cut for a slot and glued to it so it holds the larger 4WD spring tight. I searched high and low for a perch from another model that would work, no dice. It's bigger diameter than a 2WD, but narrower than a Traxxas and other manufacturers springs. The solution is probably to just swap the upper and lower perches and trash these springs, or do like we did on our 4WD and go with a completely new unit.

The side by side pic is 4WD stock shock right, 4WD shock with 10mm spacers, rod end, 2WD modified perch on left.

It makes the ride height (with the bare minimum preload to keep the spring perch from falling out, can't go any less) no bueno. So we ended up putting the 2WD springs on the 4WD shocks with a 2WD unmodified upper and lower perch, and got this.

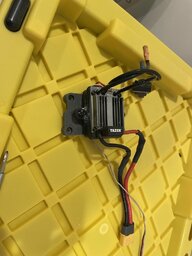

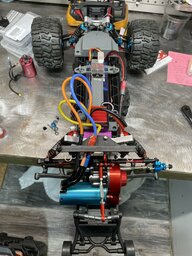

Final pics are the mock up of how we are replacing the stock transmission to rear shock tower brace and transmission to rear bumper brace (for us, now wheelie bar not rear bumper). Yes, that is a 3mm drill bit in the rear bumper...I didn't have any M3 long enough on hand to mock something up LOL

The side by side pic is 4WD stock shock right, 4WD shock with 10mm spacers, rod end, 2WD modified perch on left.

It makes the ride height (with the bare minimum preload to keep the spring perch from falling out, can't go any less) no bueno. So we ended up putting the 2WD springs on the 4WD shocks with a 2WD unmodified upper and lower perch, and got this.

Final pics are the mock up of how we are replacing the stock transmission to rear shock tower brace and transmission to rear bumper brace (for us, now wheelie bar not rear bumper). Yes, that is a 3mm drill bit in the rear bumper...I didn't have any M3 long enough on hand to mock something up LOL

Attachments

-

410934B4-8C0D-4708-988B-8DE611A6389B.jpeg118.4 KB · Views: 6

410934B4-8C0D-4708-988B-8DE611A6389B.jpeg118.4 KB · Views: 6 -

C96DFDB6-4DA0-4A22-A18A-713512FC215F.jpeg111.3 KB · Views: 6

C96DFDB6-4DA0-4A22-A18A-713512FC215F.jpeg111.3 KB · Views: 6 -

29A4CE2D-49F9-465F-B243-88D5BE4EC994.jpeg256.5 KB · Views: 7

29A4CE2D-49F9-465F-B243-88D5BE4EC994.jpeg256.5 KB · Views: 7 -

733494BB-A8FA-40CE-821B-083790B05B45.jpeg206 KB · Views: 7

733494BB-A8FA-40CE-821B-083790B05B45.jpeg206 KB · Views: 7 -

0EFD8B54-88C3-4998-8540-25A74AB177B4.jpeg165.6 KB · Views: 6

0EFD8B54-88C3-4998-8540-25A74AB177B4.jpeg165.6 KB · Views: 6 -

AAF8156F-90FA-4F96-AA46-33B860156B50.jpeg195.9 KB · Views: 6

AAF8156F-90FA-4F96-AA46-33B860156B50.jpeg195.9 KB · Views: 6 -

A2C638BE-A3C2-4607-8ED5-1BFF0E9CF77B.jpeg148.8 KB · Views: 7

A2C638BE-A3C2-4607-8ED5-1BFF0E9CF77B.jpeg148.8 KB · Views: 7

Last edited: