slick2500

Well-Known Member

- Messages

- 486

- Location

- Rapid City SD

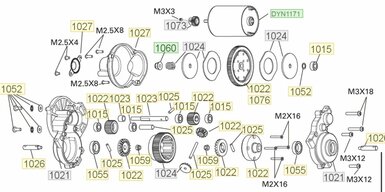

Dude I'm telling you the spurs are warped not the housing. Pull the spur and lay it on a piece of glass bet you dollars to donuts it will rock.does anyone have warped motor mounts like im getting all the time with circuit? I have unequal gear mesh on my spur and pinion leading to spur stripping