Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

circuit 2wd

- Thread starter ecx4343

- Start date

jimboEcx500

Member

- Messages

- 16

ill send photo tomorrow}} not sure it pulls right to. i can hear grinding sound. strange coz

everything is new. metal diff, upgraded axles, new slipper ive got the 87t hot racing metal spur on there to

everything is new. metal diff, upgraded axles, new slipper ive got the 87t hot racing metal spur on there to

ill send photo tomorrow}} not sure it pulls right to. i can hear grinding sound. strange coz

everything is new. metal diff, upgraded axles, new slipper ive got the 87t hot racing metal spur on there to

The truck pulls right when driving?

Grinding sound with motor/trans on bench or just when installed in vehicle?

Sounds like you may want to pull that differential apart and see

jimboEcx500

Member

- Messages

- 16

tested now and wheels off ground spin ok. but soon as i put on road fullThe truck pulls right when driving?

Grinding sound with motor/trans on bench or just when installed in vehicle?

Sounds like you may want to pull that differential apart and see

throttle it still grinds. all gear teeth look ok in trans. should i check inside new diff ?

tested now and wheels off ground spin ok. but soon as i put on road full

throttle it still grinds. all gear teeth look ok in trans. should i check inside new diff ?

Before you pull it entirely apart, take pinion off motor. Spin wheels by hand in air, see if grinding. Other wheel should spin opposite direction just as fast. Repeat both sides. Grinding sound?

Put truck on flat ground like pavement and push as hard as you can. Still grinding sound?

jimboEcx500

Member

- Messages

- 16

tried all this other wheel spins opposite with no grinding. only happens under acceleration when running car.Before you pull it entirely apart, take pinion off motor. Spin wheels by hand in air, see if grinding. Other wheel should spin opposite direction just as fast. Repeat both sides. Grinding sound?

Put truck on flat ground like pavement and push as hard as you can. Still grinding sound?

and when i tighten slipper now spur gear seems tight to diff case ? do u think i could drill hole in input shaft and use traxxas slipper ? i see one guy on youtube that's done it }}

tried all this other wheel spins opposite with no grinding. only happens under acceleration when running car.

and when i tighten slipper now spur gear seems tight to diff case ? do u think i could drill hole in input shaft and use traxxas slipper ? i see one guy on youtube that's done it }}

Ok, next test is put the pinion back on and take the axles out. Grinding when motor running back or forth?

You mentioned the spur hits the case when you tighten it down but you didn’t answer my question if you put that spacer back in behind the spur correctly? With everything fully tightened, you should have clearance between the spur and trans case.

I drilled the shaft once. I snapped it in half at the spot it was drilled within a week

jimboEcx500

Member

- Messages

- 16

no grinding with axles out. with spacers its flatter side against spur gear ? can u show in photo }}Ok, next test is put the pinion back on and take the axles out. Grinding when motor running back or forth?

You mentioned the spur hits the case when you tighten it down but you didn’t answer my question if you put that spacer back in behind the spur correctly? With everything fully tightened, you should have clearance between the spur and trans case.

I drilled the shaft once. I snapped it in half at the spot it was drilled within a week

no grinding with axles out. with spacers its flatter side against spur gear ? can u show in photo }}

If you took the axles out and there is no grinding when the motor spins the trans, but there is also no grinding when just rotating the wheels by hand or pushing the truck back and forth, that means the problem is the differential. Take the transmission back apart, take apart the diff, make sure the spider gears and shafts are all in correctly.

jimboEcx500

Member

- Messages

- 16

ok i get it. im about to do all this. ive noticed trans case where the bearing on input shaft goes in behind spacer its worn inside case and theres a lip now i think this why the 5x10 bearing does not sit flush inside any chance u could send photo of how spider gears meant to look ? cheersIf you took the axles out and there is no grinding when the motor spins the trans, but there is also no grinding when just rotating the wheels by hand or pushing the truck back and forth, that means the problem is the differential. Take the transmission back apart, take apart the diff, make sure the spider gears and shafts are all in correctly.

jimboecx380

Member

- Messages

- 7

ok i get it. im about to do all this. ive noticed trans case where the bearing on input shaft goes in behind spacer its worn inside case and theres a lip now i think this why the 5x10 bearing does not sit flush inside any chance u could send photo of how spider gears meant to look ? cheers

jimboecx380

Member

- Messages

- 7

Here bearing only goes half way in hole

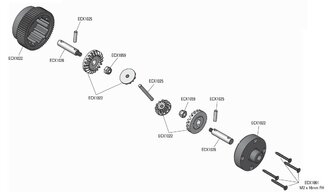

Does this all look correct?

Does this all look correct?

Attachments

Here bearing only goes half way in hole

Does this all look correct?

the differential looks okay but you only have the planetaries shown (some people call them sun gears, the big ones). where is the dog bone with the two spider gears?

yeah, that blue bearing should definetely seat all the way into the housing. if you can only fit a 5x9x4 in there, try cleaning it out or replacing the housing. that extra play the smaller bearing is going to allow is going to allow the input shaft to move around and spread apart from the idler. It's probably the source of the grinding and it may start to show odd wear pattern on the input shaft gear and top shaft gear, and would make sense why it only happens under load. it would also explain why the spur/clutch is able to hit the housing in certain cases.

what does the front side of the transmission housing look like now? (the side the clutch goes on)? does it have a wear mark from where the spur is contacting it? the marks on your clutches are from the heat of the clutch slipping

jimboEcx500

Member

- Messages

- 16

the spider gears are in the diff. first time ive taken it apart. i got spear metal one to. the bearing use to go all way in obviously grinding worn it all out. i think housing side looks ok but ive ordered new transmission case. ill check again. should i replace input shaft then ? input shaft gear and top gear look all ok there is no wear i checked all teeth.. u think to replace slipper pads aswell ?the differential looks okay but you only have the planetaries shown (some people call them sun gears, the big ones). where is the dog bone with the two spider gears?

yeah, that blue bearing should definetely seat all the way into the housing. if you can only fit a 5x9x4 in there, try cleaning it out or replacing the housing. that extra play the smaller bearing is going to allow is going to allow the input shaft to move around and spread apart from the idler. It's probably the source of the grinding and it may start to show odd wear pattern on the input shaft gear and top shaft gear, and would make sense why it only happens under load. it would also explain why the spur/clutch is able to hit the housing in certain cases.

what does the front side of the transmission housing look like now? (the side the clutch goes on)? does it have a wear mark from where the spur is contacting it? the marks on your clutches are from the heat of the clutch slipping

Last edited:

jimboecx380

Member

- Messages

- 7

This inside my other one same )) this just speari did not know there were spider gears in the diff first time ive taken it apart. i got spear metal one here ill

check inside that one. the bearing use to go all way in obviously grinding worn it all out. i think housing side looks ok. ill check again. should i replace input shaft then ? input shaft gear and top gear look all ok there is no wear i checked all teeth.. u think to replace slipper pads aswell ?

Attachments

the spider gears are in the diff. first time ive taken it apart. i got spear metal one to. the bearing use to go all way in obviously grinding worn it all out. i think housing side looks ok but ive ordered new transmission case. ill check again. should i replace input shaft then ? input shaft gear and top gear look all ok there is no wear i checked all teeth.. u think to replace slipper pads aswell ?

I think the shaft will be fine. You could roll it on a table and check to make sure it’s straight I did bend one. If you scuff up those pads they’ll probably be fine. I make my own out of gasket paper and lightly glue them to the spur. Get that case and bearing replaced and retest I think that’ll solve your grinding issue

This inside my other one same )) this just spear

Yeah that looks right, two planetaries (sun the big one) two spiders on a dog bone. Since there is no option for a locker anymore for these you can put some real thick fluid in there or pack it with putty/epoxy

jimboEcx500

Member

- Messages

- 16

its straight hopefully be fine. what thickness gasket paper do u use? transmission case coming soonI think the shaft will be fine. You could roll it on a table and check to make sure it’s straight I did bend one. If you scuff up those pads they’ll probably be fine. I make my own out of gasket paper and lightly glue them to the spur. Get that case and bearing replaced and retest I think that’ll solve your grinding issue

just need some dry weather in uk to test it out }}

cheers for u help

WithinU

Well-Known Member

- Messages

- 514

- Location

- Land of Oz

Does the UK ever have dry weather?just need some dry weather in uk to test it out }}